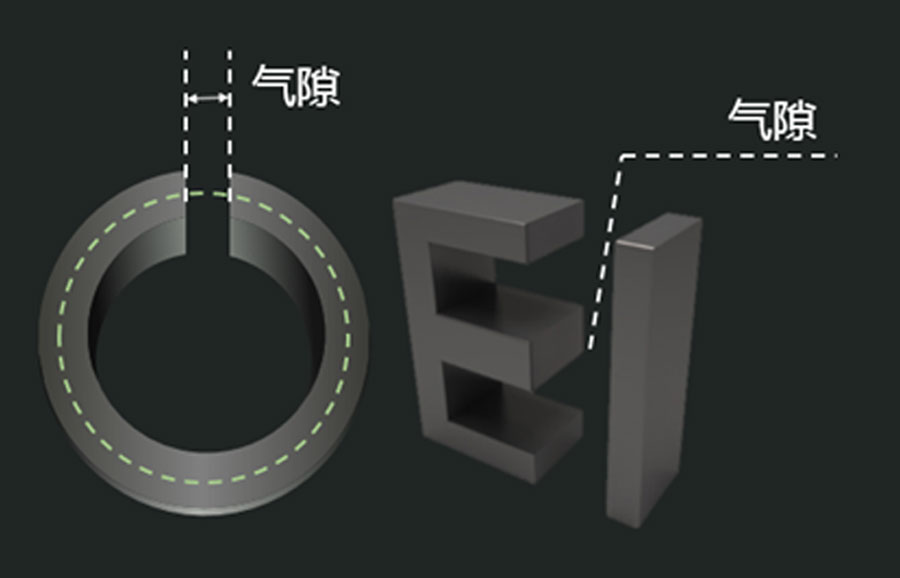

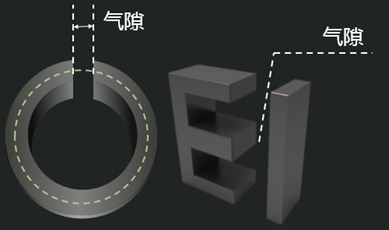

What is an air gap?

The air gap of the magnetic core refers to a part of the magnetic circuit composed of air, hence it is called the air gap, abbreviated as the air gap. For example, in the EI type magnetic core, there is always a gap in the combination of E and I, and there is an air gap in the magnetic circuit. There is a gap in the middle of the circular magnetic ring, and the gap is the air gap.

What is the use of air gaps?

1. Air gap can reduce magnetic permeability

2. Increase saturation current

3. Increase the ability to store energy

4. It can also reduce residual magnetism

5. Design requires selecting the appropriate air gap size

The following explains the reasons for these effects from a microscopic perspective.

Wrap a circular magnetic ring around the coil, and after applying current, the magnetic core reaches saturation, indicating that all magnetic domains inside have been arranged in an orderly manner.

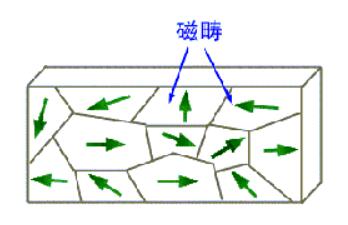

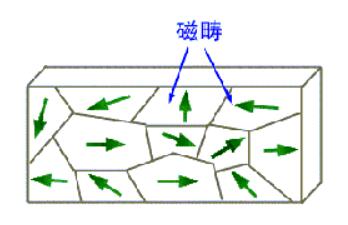

The so-called magnetic domains refer to small regions within a magnetic material, each containing a large number of atoms. The magnetic moments of these atoms are arranged neatly like small magnets, but the directions of atomic magnetic moments between adjacent different regions are different, as shown in the figure. The interface between various magnetic domains is called the magnetic domain wall. Macroscopic objects generally have many magnetic domains, so the magnetic moment directions of the domains are different, and the results cancel each other out. The vector sum is zero, and the magnetic moment of the entire object is zero, so it cannot attract other magnetic materials. That is to say, magnetic materials do not display magnetism to the outside under normal circumstances. Only when a magnetic material is magnetized can it show magnetism to the outside world.

At this point, an air gap is opened on the magnetic ring to remove a portion of the magnetic core, and this portion of the magnetic domain is also removed. The magnetic domains at the air gap were originally arranged in an orderly manner, equivalent to a small magnet, which had a positive force on the ordered arrangement of the magnetic domains next to the air gap. Now they have been removed, and the force has decreased, which means that the magnetism has decreased. The magnetic domains cannot be arranged in an orderly manner, further leading to a decrease in the force on adjacent magnetic domains next to the air gap. One by one, the magnetic domains of the entire magnetic core are not arranged in an orderly manner more. Therefore, the magnetic ring with an open air gap is not magnetically saturated.

要To arrange the magnetic domains in an orderly manner again, a greater current must be applied until they are saturated again.

Therefore, it can be seen that increasing the air gap increases the saturation current. Overall, as the ordered arrangement of magnetic domains decreases, the generated magnetic flux also decreases, i.e. the magnetic permeability decreases. It can also be seen that the positive interaction force between magnetic domains is weakened, so the residual magnetism decreases when there is no current.

Assuming that there is no air gap, the magnetic field strength corresponding to complete magnetic saturation is Bm. After adding an air gap, increase the current to make all magnetic domains of the magnetic ring reach saturation again. What should the magnetic field strength be at this time? Let's imagine that all the magnetic domains in the magnetic ring are arranged at saturation current, which means that the most difficult domain to deflect happens to deflect at this time. Regardless of whether we add an air gap or not, if the most difficult domain deflects, the magnetic field strength at its location is Bm. So after adding an air gap, the magnetic field strength at saturation is still Bm, which remains unchanged compared to before.

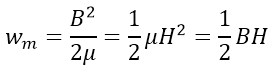

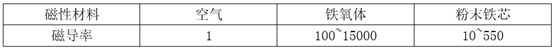

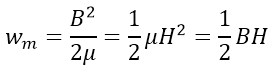

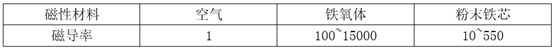

The magnetic field energy density is the magnetic field energy contained per unit volume, and its formula is the square of B divided by 2 μ, The energy storage of the magnetic core remains unchanged. And the magnetic permeability at the air gap μ It has become air, and the magnetic permeability of the air is generally only a few tens to a few thousand times that of the magnetic ring material. Therefore, the energy storage density at the air gap has increased by hundreds or thousands of times.

Therefore, the air gap increases the ability to store energy.

So the larger the air gap, the better? Obviously not, because when the air gap is maximum, there is no magnetic ring, which is an empty core inductance. Theoretically, the empty core inductance never saturates, and there is no upper limit to energy storage, as long as the current is large enough. In reality, there is always an upper limit to the current, and even if it is too large, the wire cannot carry it.

In fact, we say that the air gap increases the upper limit of energy storage, referring to energy storage under the condition of both being saturated. In cases where both are unsaturated, applying the same current without an air gap results in higher energy storage, as the energy density formula is equal to half of the μ Multiply by the square of H, and at the same current, H is the same, while without an air gap, the magnetic permeability is higher. The air gap is too large, and due to the low magnetic permeability, it is difficult to improve the inductance, so it is necessary to choose a suitable air gap size.

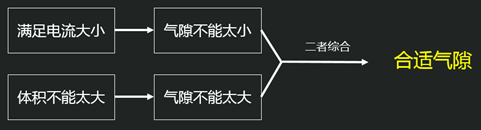

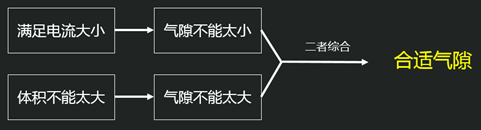

Appropriate air gap size

So, what is the appropriate air gap size?

In circuit design, the maximum input and output current, as well as the inductance value, are usually determined. So when we ensure the maximum current is applied, the inductance magnetic core does not saturate, so the air gap cannot be too small, otherwise it is easy to saturate. It is also necessary to consider factors such as cost and volume, and minimize the air gap as much as possible in order to achieve greater sensitivity with a smaller volume. The combination of the two results in an appropriate air gap size. This is only considered from the perspective of magnetic saturation, but in reality, it is more complex and requires consideration of various aspects such as material type, temperature, loss, leakage inductance, etc.